ECO – Efficient assessment of Conformity in railway traffic

06/2011 - 05/2013

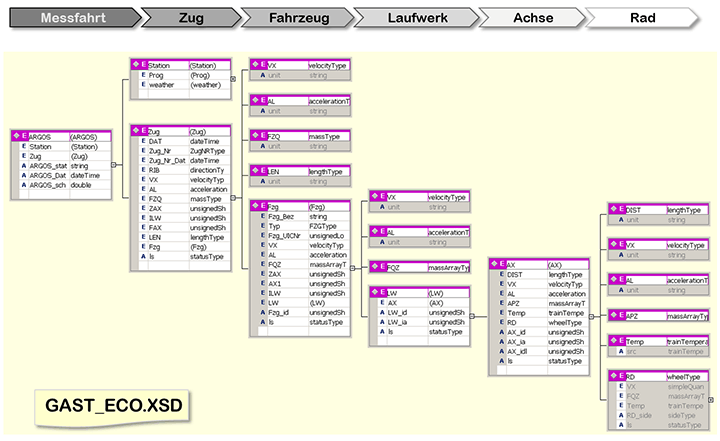

Schema for cross-border data exchange, as developed and tested in ECO

A safe and efficient train service requires the continuous inspection of the rolling stock. So far, the checks of the technical safety are performed by the carriage examiner while building up the train and by the traffic controller when the train passes through the station. These checks are primarily audio-visual, and the quality depends on the individual experience of the persons involved.

In the project ECO, this problem was addressed by a technical solution. Due to the automation in the safety equipment and the related staff savings in the stations, an automated train monitoring is essential. Automated monitoring allows parameters to be measured far more exactly, compared to visual checks (or even to be measured at all in the first place).

A series of previous research projects provides a good foundation for automated inspections of railway vehicles concerning overloads, out-of-round wheels, and running performance. Research in Austria is leading in this field, which was also impressively demonstrated by a series of international benchmark test runs in Switzerland. Since these vehicle irregularities are directly related to higher maintenance costs, railway infrastructure operators are also showing increasing interest in their monitoring, in order to withdraw them from the track or charge them for the damage (costs-by-cause principle…).

However, automated inspections will only gain recognition if they are performed on the basis of the European TSI Conventional Rail Rolling Stock and TSI HS Rolling Stock. Besides, following the European idea, it is very important to have the data of automated inspections also accepted beyond a country's borders. It is beyond dispute that automated checkpoints will see increasing application within the next 2 to 5 years. Thus, it is necessary to think about the data exchange and the cross-border acceptance of these measured data, to avoid expensive parallel deployments when building checkpoints on both sides of a border.

The project ECO demonstrated how efficient and thus cost-saving the continuous inspection of the rolling stock can be performed even in bilateral cooperation. The cooperation between ÖBB and SBB also proved how well this can work in a bilateral data exchange. It must be noted that the related investments will cause additional costs for a short term, but will pay off soon after the area-wide deployment of the system.

For more on data exchange, see RMX2!