SIMOOR – Simulation of Out-Of-Roundness of Railway Wheels

SIMOOR – Simulation of Out-Of-Roundness of Railway Wheels

09/2006 – 08/2008

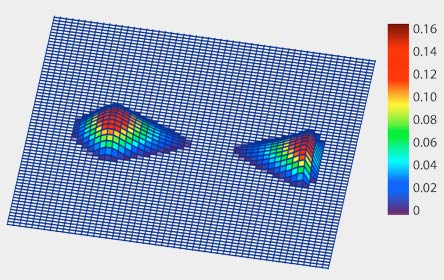

Evolution of wear on the tread (animation)

Out-of-roundness in railway wheels, e.g. flat spots, are a significant contributor to increased maintenance costs. For the operator the reliable detection of vehicles violating the operational specifications is essential; in the near future also under the light of usage fees. First, out-of-roundness significantly affects operational safety and comfort, and second, the maintenance costs of cars and infrastructure increase. In addition, out-of-round wheels are highly responsible for noise emissions.

In this project the basic causes of out-of-round railway wheels are to be examined closer. Using computer simulations, the interaction between rail and wheel will be studied. In particular, the variations of normal forces will be analyzed, which cause an essential excitation of the infrastructure and thus can lead to overstressing of the rail components.

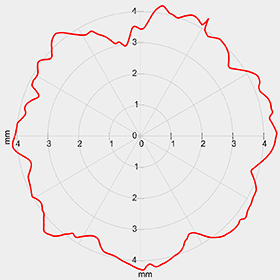

Out-of-roundness in one cross section (polygonization)

Non-elliptical 2-point contact.

In a long term feedback loop the described normal force variations can reinforce existing out-of-roundness. It is therefore very important to keep the normal force variations low, in order to optimize the maintenance and the life cycle costs (LCC), which is in turn only possible if the basic cause of out-of-roundness is known.

Existing simulation tools able to simulate the interaction between car and rail can only be applied under the assumption of perfect conditions of wheel and rail. On this foundation, the simulation tool to be designed in this project is intended to represent the roll-off process of out-of-round railway wheels under normal operating conditions, enabling the deduction of the mechanisms causing out-of-roundness in the wheel/rail system.

For this purpose, different wear models are compared, considering also plastic deformation and non-elliptical contact. By means of parameter studies the system behavior is analyzed, leading to a deeper understanding of the processes involved in the emergence of out-of-roundness. In the further stages the simulation model is calibrated and fine-tuned with real-life measurement data.

The use of simulation tools can thus eliminate the necessity of installing different system variations in the track, along with expensive test runs, and help in eliminating non-effective system configurations. Maintenance methods could be optimized just as quickly, and besides a noise reduction, a significant cost reduction can be achieved.